Pushing the boundaries of innovation, Balfour Beatty and Versarien are joining forces to develop groundbreaking construction materials that aim to reduce carbon footprints and enhance project efficiency.

Balfour Beatty, a prominent London-based construction company, has teamed up with Versarien, a leading advanced materials engineering firm, to create 3D-printable mortars infused with graphene. This innovative collaboration, announced on October 1, is expected to yield materials that not only push the envelope in terms of technology but also support sustainable construction practices.

Breaking New Ground in Construction Materials

The partnership focuses on creating specialized mortars for civil engineering projects, utilizing Versarien’s unique graphene admixture, Cementene, to enhance strength and reduce the carbon impact. Together, the teams will explore three distinct mortar formulations, one of which will use regionally sourced materials while the others incorporate Cementene to amplify the mortar’s performance.

Balfour Beatty’s Highways division will test the materials in real-world conditions, evaluating them on key performance indicators such as longevity, cost-efficiency, and overall effectiveness compared to traditional construction options. By bringing these advanced materials into practical use, they hope to redefine standards for construction durability and environmental responsibility.

Local Solutions for a Global Challenge

A key goal of the collaboration is to develop a resilient, UK-based supply chain for these pioneering mortars. The team is working to identify suppliers, integrate quality control protocols, and establish distribution channels both within the UK and beyond. This approach will not only support local businesses but also ensure that the development of these innovative materials is sustainable from production to implementation.

“Partnering with Balfour Beatty on this exciting project is an incredible opportunity to advance low-carbon, 3D-printable solutions for the construction industry. We’re thrilled to see how our Cementene-enhanced mortars can push the boundaries of sustainable civil engineering,” said Stephen Hodge, CEO of Versarien.

Previous Collaborations and Future Potential

This partnership builds on the companies’ previous work through initiatives like the Roads Research Alliance and the University of Cambridge’s Digital Roads of the Future project. Both programs aim to modernize the UK’s infrastructure using innovative, data-driven methods.

While Balfour Beatty has not yet confirmed whether these materials will be tested in projects outside the UK, this collaboration signals a step forward in developing eco-conscious construction techniques that could have far-reaching implications.

Broader Trends in 3D-Printing for Construction

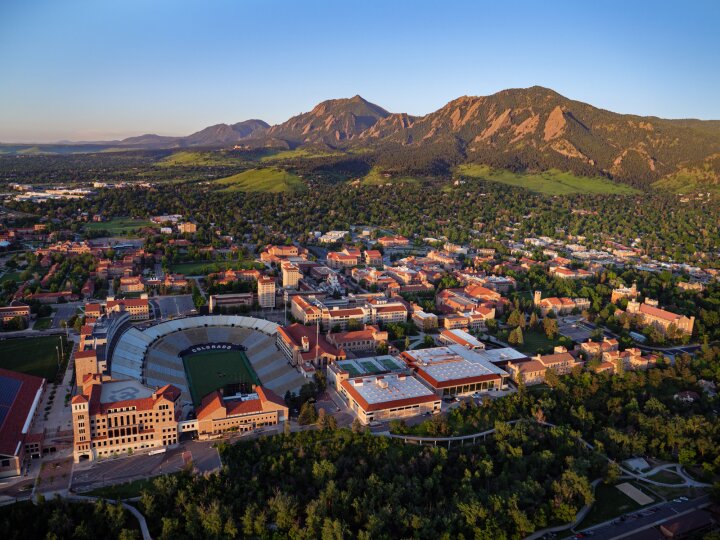

The world of construction is increasingly turning to 3D-printing technologies to address challenges related to sustainability and efficiency. For instance, Massachusetts Institute of Technology researchers recently developed a form of 3D-printed glass bricks that demonstrate the strength of traditional concrete blocks. Meanwhile, Colorado-based Alquist 3D completed a sizable expansion project for Walmart, underscoring the commercial viability of 3D-printed structures.

As more companies and researchers explore the possibilities of 3D printing in construction, collaborations like the one between Balfour Beatty and Versarien pave the way for more efficient and sustainable building practices that can revolutionize the industry.

Sources: www.constructiondive.com, www.agc.org, www.enr.com, www.bls.gov, www.yahoo.com/news, www.thedefensepost.com