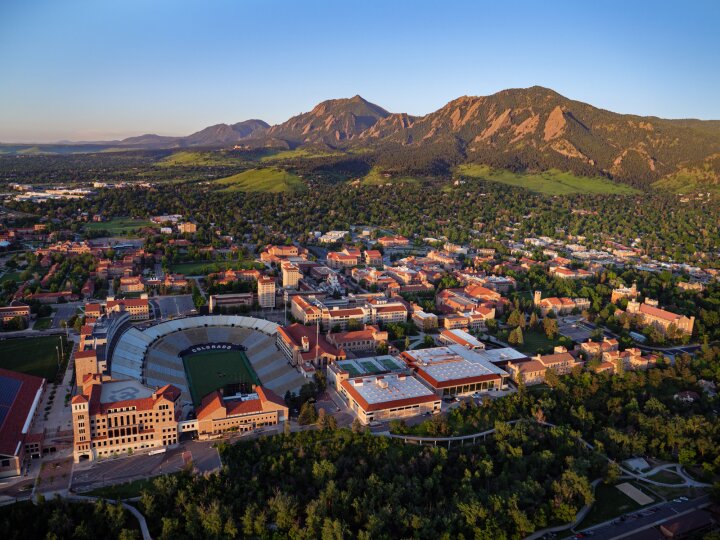

The construction industry is at a crossroads. Demand for infrastructure and development is skyrocketing, yet the workforce simply isn’t keeping up. By 2025, the U.S. will need nearly half a million additional construction workers just to meet demand. The problem isn’t new—the Great Recession of 2008 wiped out 30% of the industry’s workforce, and we’ve been playing catch-up ever since.

While trade schools and apprenticeship programs are part of the solution, there’s another approach making waves: construction robotics.

Enter Concert, a modular, highly adaptable robot designed to take on some of the most repetitive and hazardous tasks on a job site. Developed by researchers at the Italian Institute of Technology, Concert isn’t just another single-function construction bot—it’s a flexible, multi-purpose machine that could redefine automation in our industry.

A Construction Robot That Adapts

Most construction robots today specialize in just one task. Hadrian X lays bricks, Hilti Jaibot drills into ceilings, and Okibo plasters and paints walls. While effective, these machines aren’t practical for the average contractor—investing in a different robot for each task just isn’t scalable.

Concert takes a different approach. Built for modularity, it consists of a mobile base and a robotic arm that can be customized for different jobs. It can drill, spray insulation, sand walls, and even transport materials up to 400 pounds. Its wheels adjust to different terrains, and its attachments swap out depending on what needs to be done.

Think of it like a Swiss Army knife for construction—one machine that can adapt to multiple tasks rather than being locked into just one.

Why Automation Has Struggled in Construction

Unlike manufacturing, where automation has thrived in predictable, controlled environments, construction sites are chaotic. Every site is different, presenting unique challenges that make full automation difficult.

Nikolaos Tsagarakis, the lead researcher behind Concert, puts it simply:

"For a robot to be useful and efficient at a construction site, it must be able to adapt and have some degree of autonomy."

That’s exactly what the Concert team set out to achieve.

To make the robot function in real-world conditions, they equipped it with laser scanners, 3D cameras, and ultrasonic sensors, allowing it to perceive its surroundings, avoid obstacles, and interact with workers. During tests in Krakow, Poland, Concert successfully:

- Drilled into walls and ceilings with millimeter precision

- Sprayed insulation, eliminating human exposure to toxic materials

- Sanded walls, taking on repetitive labor-intensive tasks

- Assisted in transporting heavy materials, reducing strain on workers

Notably, Concert was able to navigate from a jobsite parking lot to a designated work area completely on its own, proving its potential for autonomy.

Bridging the Gap Between Workers and Robots

The big question that always comes up when discussing automation: Will robots take our jobs?

Tsagarakis doesn’t think so—and neither do we. Instead of replacing workers, robots like Concert could make construction jobs more attractive by eliminating the most dangerous and tedious tasks.

At Paragon Construction Consulting, we’ve seen firsthand how difficult it is to recruit new talent into the field. The next generation of workers wants safer, more technologically advanced job sites. If robots can take on tasks like sanding, drilling, and heavy lifting, that leaves more room for skilled tradespeople to focus on higher-value, technical aspects of construction.

Like past innovations—the steam engine, electricity, AI—construction robotics won’t eliminate jobs; they’ll create new ones. Skilled workers will still be essential, but they’ll work alongside intelligent machines that make projects safer, faster, and more efficient.

What’s Next for Concert?

Concert is still in development, but its creators hope to bring it to market within two to three years. After receiving a $3 million grant from the EU, the research team is now seeking funding to launch a startup and scale production.

Will Concert and other modular robots become a staple of construction sites in the near future? We think so. The industry is evolving, and embracing technology isn’t just an option—it’s a necessity.

At Paragon, we believe in the power of innovation to reshape the built environment. Whether it’s automation, AI-driven project management, or advanced materials, the companies that adapt will be the ones that thrive.

The future of construction isn’t about choosing between humans and robots—it’s about finding new ways for them to build together.